Customised Solutions for Complex Medical Applications

New and disruptive technologies such as surgical robotics and AI are revolutionizing the medical equipment industry, Creating a new dynamic marketplace with a drive towards value-based care.

Staying ahead of the curve requires innovation in all areas of product design including material selection to support adoption of complex new technologies. Our advanced ceramics materials offer a wide range of unique properties that address complex engineering challenges and unlock huge performance benefits.

Why Work with CeramTec?

45 Years of Medical Heritage

With over 100 years of experience in technical ceramics and more than 45 years of expert know-how in medical technology, we offer our customers globally networked engineering and solution competence. This is essential for the safety-critical components we supply to customers in the medical world.

Services à la carte

Our broad range of services reflects the complete product life cycle from ideation to research & development through engineering and manufacturing.

We offer a range of services to support you in your innovation process.

We partner with you to find the right solution that aligns with your portfolio strategy and helps you to achieve the desired level of differentiation.

Our experienced team has the resources and expertise to bring a different perspective that will enhance your innovation process.

Above that we can help educate on material selection and translate your requirements into a product specific technical specification.

Our dedicated R&D teams provide an end-to-end OEM service to develop your customised product.

We support you with flexible solutions to reduce project risk at an early stage, through technical discussions and feasibility projects.

We have identified the importance of expertise and collaboration across component interfaces and process steps.

Our engineering team consists of specialists with decades of experience in the field of ceramics and ultrasonic tecchnologies.

We offer a wide range of engineering services from 3D scanning, CAD modeling and design evaluation through FE-Analyses, risk assessment, and testing.

Tooling and manufacturing fixture requirements are developed and built internally based upon a very broad skill set.

Benefit from highly structured processes for developing prototypes and made-to-order products ensuring best-in-class results.

Our capabilities cover all your manufacturing needs from one-off, individual manufacturing, or made-to-order batch production through pilot series and large-scale production.

Our automation expertise enables flexibility to scale rapidly and provide low-cost solutions for piezo-ceramic and ultrasonic products.

Manufactured components range from micro size with the finest radius and tolerances to large, highly complex products with free form surfaces.

To ensure the reliability of our processes, all sites are at least certified according to ISO 9001, sections according to ISO / IATF 16949 and (e.g., medical sensors and transducers)

DIN EN ISO 13485.

We offer a range of services to support you in your innovation process.

We partner with you to find the right solution that aligns with your portfolio strategy and helps you to achieve the desired level of differentiation.

Our experienced team has the resources and expertise to bring a different perspective that will enhance your innovation process.

Above that we can help educate on material selection and translate your requirements into a product specific technical specification.

Our dedicated R&D teams provide an end-to-end OEM service to develop your customised product.

We support you with flexible solutions to reduce project risk at an early stage, through technical discussions and feasibility projects.

We have identified the importance of expertise and collaboration across component interfaces and process steps.

Our engineering team consists of specialists with decades of experience in the field of ceramics and ultrasonic tecchnologies.

We offer a wide range of engineering services from 3D scanning, CAD modeling and design evaluation through FE-Analyses, risk assessment, and testing.

Tooling and manufacturing fixture requirements are developed and built internally based upon a very broad skill set.

Benefit from highly structured processes for developing prototypes and made-to-order products ensuring best-in-class results.

Our capabilities cover all your manufacturing needs from one-off, individual manufacturing, or made-to-order batch production through pilot series and large-scale production.

Our automation expertise enables flexibility to scale rapidly and provide low-cost solutions for piezo-ceramic and ultrasonic products.

Manufactured components range from micro size with the finest radius and tolerances to large, highly complex products with free form surfaces.

To ensure the reliability of our processes, all sites are at least certified according to ISO 9001, sections according to ISO / IATF 16949 and (e.g., medical sensors and transducers)

DIN EN ISO 13485.

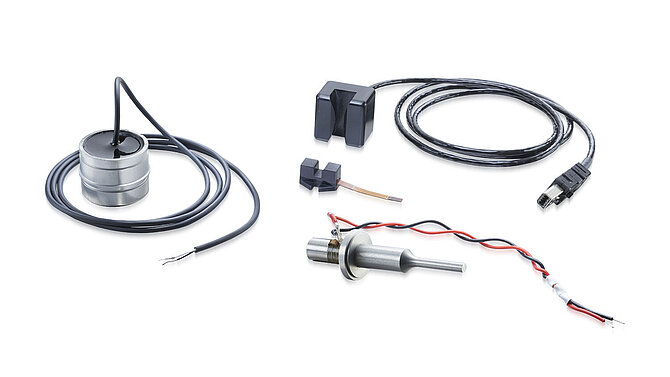

Reducing Time to Market for Critical Medical Ultrasonic Sensors & Transducers

In order to design new, innovative ultrasonic sensors and transducers the use of advanced multiphysics numerical computer modelling is advised. These modelling tools depend heavily on repeatable fundamental piezoceramic material properties to avoid designing by a trial-and-error approach.

CeramTec with innovative service suite for high power ultrasonic surgery transducers

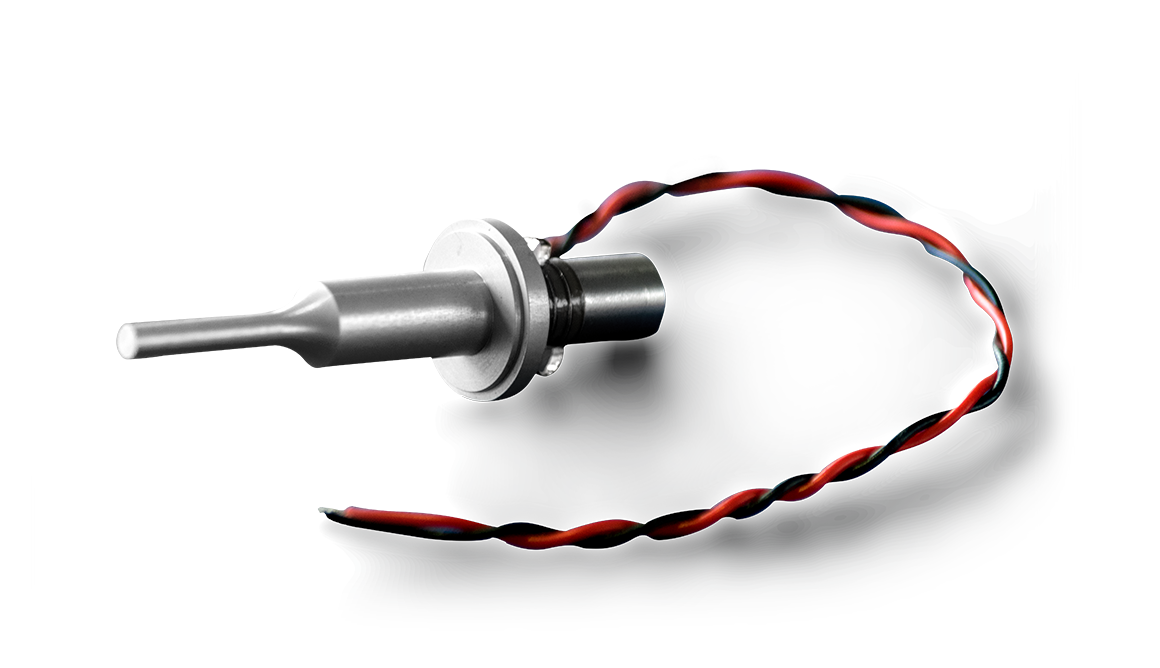

When it comes to ultrasonic transducers for medical applications, there is no one-size-fits-all solution. With vertical integration from manufacture of advanced piezoceramics to the assembly of ultrasonics sensors and transducers, technical ceramics specialist CeramTec meets the increasing demand for specified high power langevin transducers.

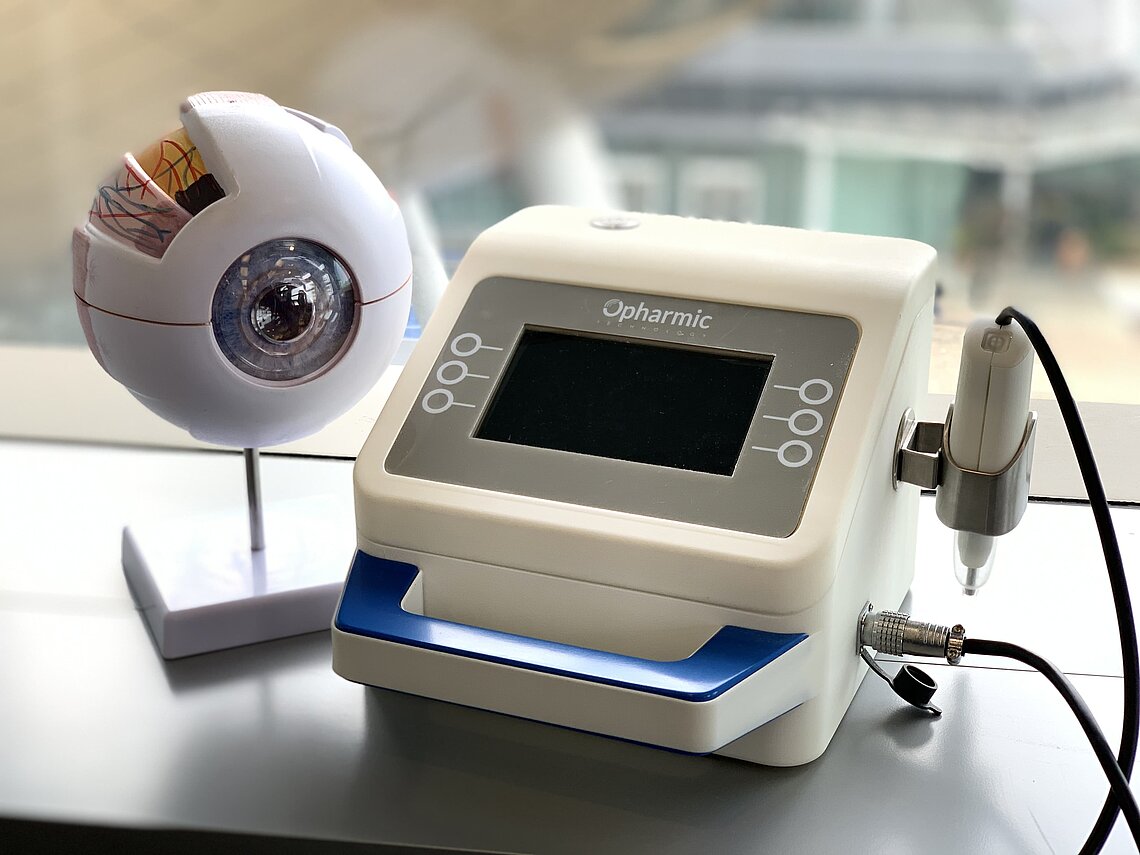

Award-winning Opharmic technology and CeramTec ceramics enable non-invasive drug delivery

Opharmic Technology (HK) Ltd. has developed a transformational ultrasonic non-invasive ocular drug delivery device with the goal of replacing intravitreal injections. The Hong Kong-based start-up is partnering with CeramTec to develop and produce the high-power transducer that enables the technology.