Securing Joint Replacement: The Taper Fixation

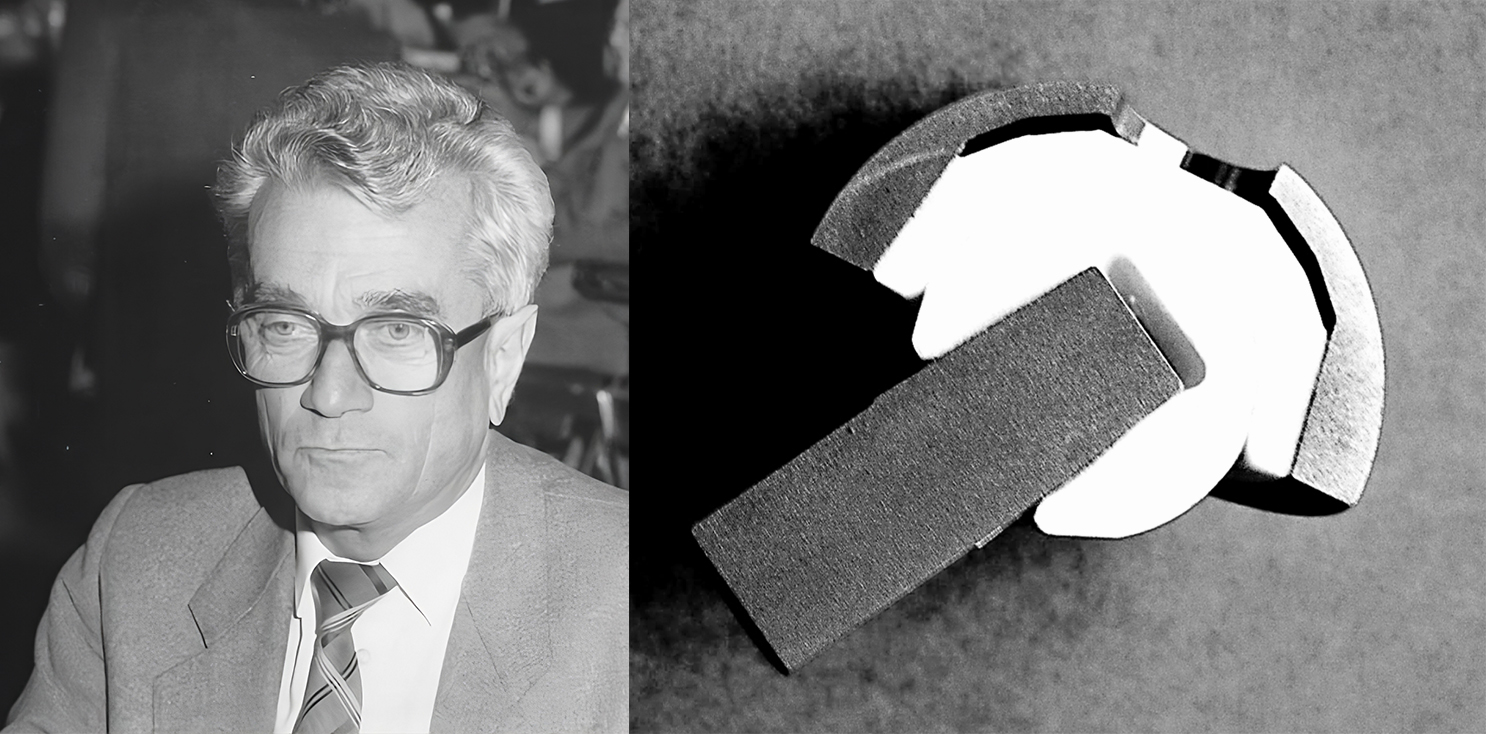

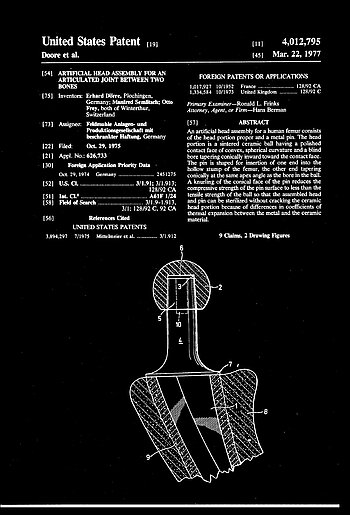

One of the pivotal advancements in the history of BIOLOX® and hip replacement is the taper fixation technique, pioneered by Dr. Erhard Dörre (Feldmühle AG), Dr. Manfred Semlitsch and Otto Frey (Sulzer Medical AG). This innovative technique, for which Dr. Dörre/Feldmühle secured a patent, has been instrumental in optimizing the performance and reliability of BIOLOX® ceramic components.

The taper fixation

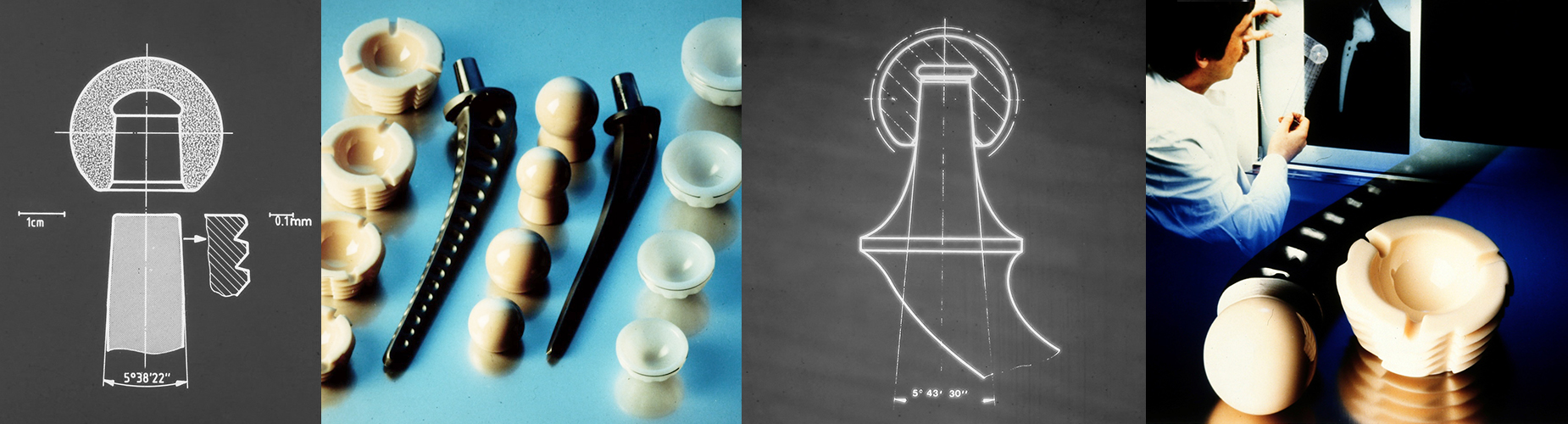

The taper fixation concept, developed by Dr. Dörre, Dr. Manfred Semlitsch and Otto Frey, addresses a critical challenge in orthopedic implant systems: securely attaching a ceramic head to a metal taper.

Prior to invention of the Dörre et al., fixation of ceramic components in joint replacements faced issues of longevity and stability, which could compromise patient outcomes. Dr. Dörre et al. introduced a fixation technique that significantly enhanced the mechanical stability and bearing capacity of BIOLOX® ceramic hip implants.

The History and Development of Taper Fixation

The concept of taper fixation was pioneered in the early 1970s by industry partners Sulzer Medical (today Zimmer Biomet based in Zug, Switzerland) and Feldmühle AG (today CeramTec GmbH in Plochingen, Germany).

Their goal was to create a safe and sustainable fixation between a ceramic femoral head and a metal stem. Special emphasis was placed on the force-fit connection, known as taper locking, by Dörre et al. The first patient application of a hip arthroplasty using taper fixation occurred in 1974, a method secured by a German patent (DE2548077B2).

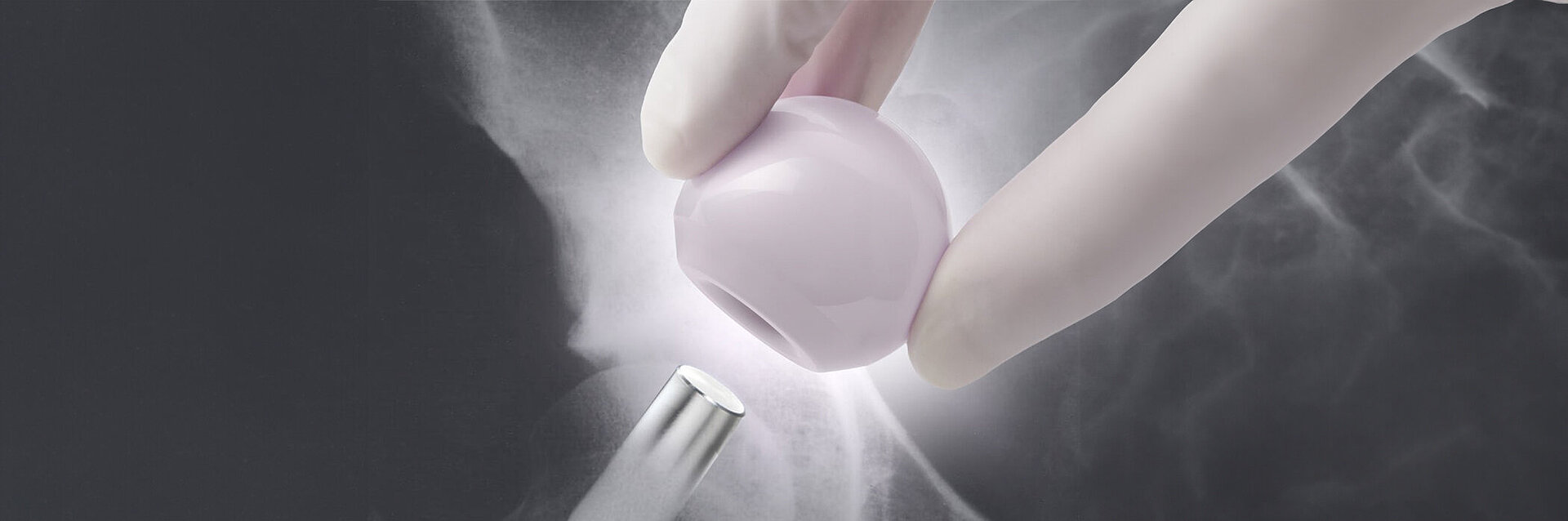

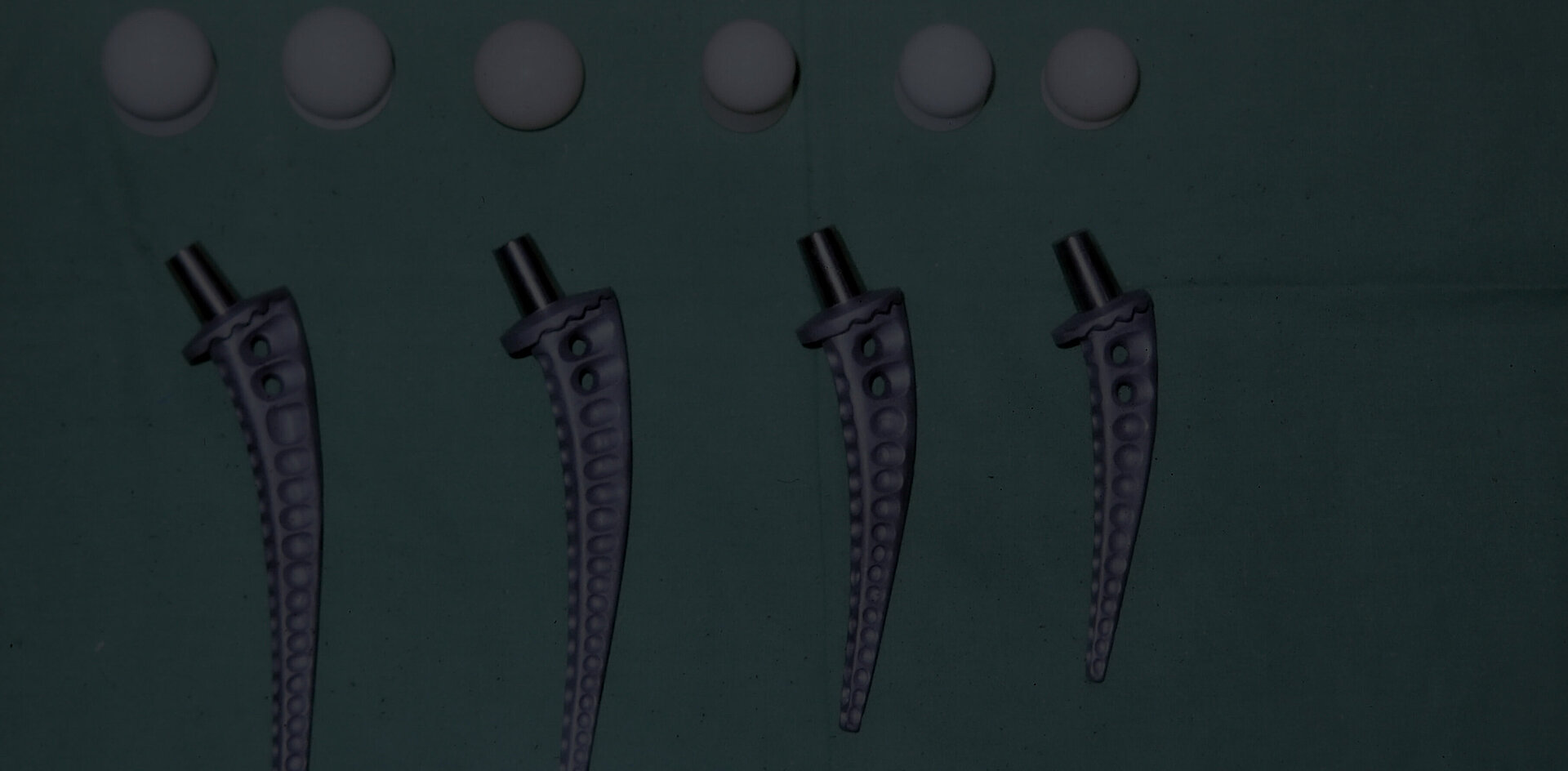

The concept consists in structuring the stem taper in a way that allows a fixed and secure engagement of the ceramic head on the taper. By affixing the head to the taper, the metal structure of the taper is deformed, allowing a safe and definite fixation.

Ensuring Precision and Compatibility in Taper Fixations

The evolution of taper fixation is a cornerstone of the favorable outcomes of the BIOLOX® ceramic components in hip constructs. While a term like "12/14 tapers" might suggest they are all identical, variations in the angle, diameter and surface structure do exist across different manufacturers which can significantly impact the fixation and performance of joint replacements. At CeramTec, we are committed to ensuring that each BIOLOX® ceramic component is released only after verification of compatibility with the appropriate stem variation.

This commitment involves meticulous design verification of the structured taper of the stem and the inner taper of the ceramic head, as well as testing to ensure that the taper fixation and the ceramic head are reliable and secure.

By addressing the nuances in taper designs — such as geometric and clearance differences — we provide solutions that uphold the highest standards of precision and patient safety.

Critical Factors in Taper Fixation

Ensuring the compatibility and proper testing of the taper fixation between a stem and a femoral head (ceramic or metal) is crucial for the success and longevity of hip arthroplasty procedures. The interface between the femoral head and the stem must be designed and tested to avoid complications (such as mechanical failure or wear) that can lead to revision surgeries. It is also important that surgeons are informed of the specific characteristics and the compatibility of the implants they are using to optimize outcomes for patients.

Benefits of Modern Modular Design

Modern hip arthroplasties employ a modular design that allows for the flexible adaptation of stem and femoral heads with various head diameters and neck lengths to suit individual patient needs during surgery. This modularity is crucial for optimizing the reconstruction of the original joint anatomy and achieving optimal biomechanics. Moreover, modular taper fixation facilitates the integration of different materials, such as metals and ceramics. Taper locking has proven effective in manufacturing and clinical use, offering high stability and durability. Additionally, during revision surgeries, this type of fixation can be disengaged to allow for the replacement of the femoral head following manufacturer guidelines.

Impact and Legacy

Taper fixation marked a turning point in the design and functionality of joint replacements.

Today, taper fixation – Clean – Dry – Impact — is a fundamental component in BIOLOX® technology-based systems. The success of the taper fixation method exemplifies how scientific ingenuity can transform medical technology. Dr. Dörre's contribution not only advanced the field of medical bioceramics but also established a new benchmark for norms and joint replacement surgeries worldwide.