The Manufacturing of BIOLOX®

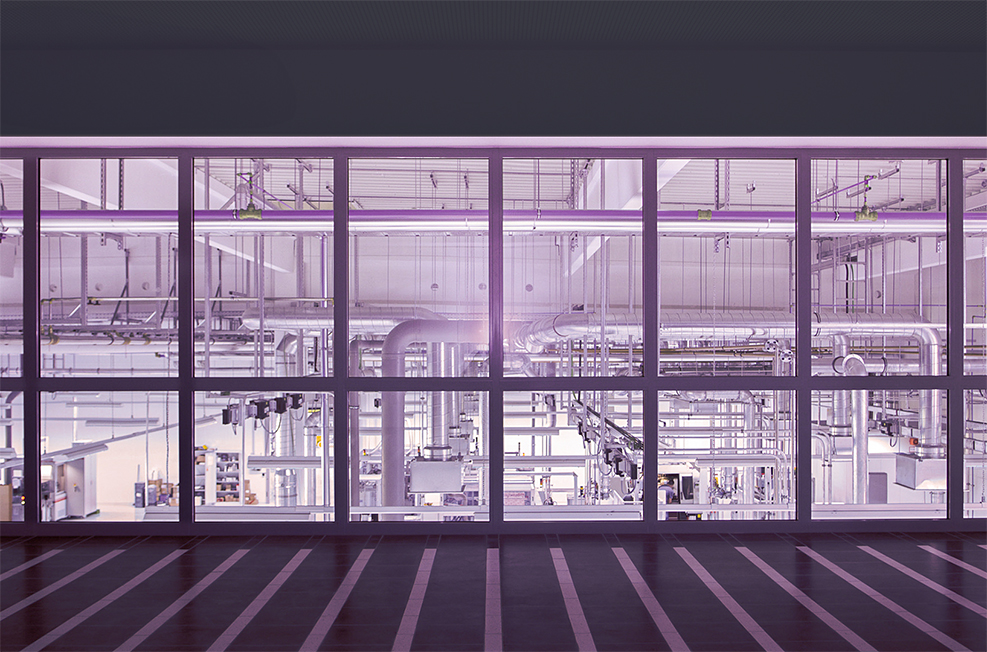

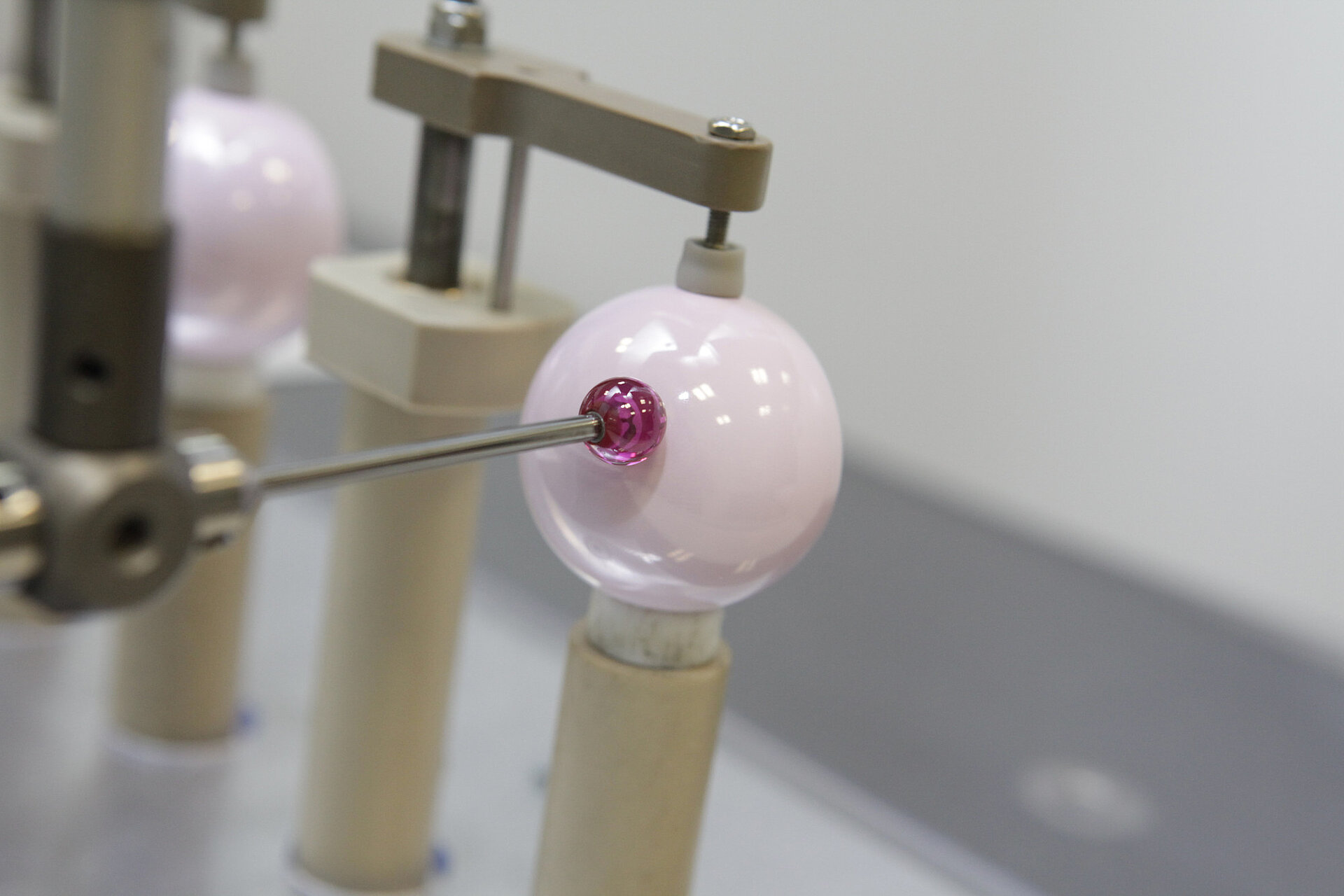

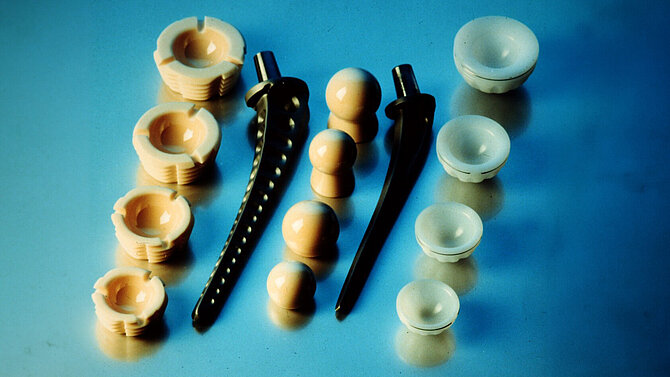

Over the past 50 years, the manufacturing processes for BIOLOX® have seen significant advancements that underscore our commitment to excellence. The year 1994 brought a transformative moment with the introduction of Hot Isostatic Pressing (HIPing), a thermal process that enhanced the structural integrity and performance of our ceramics. This period also saw the shift from mechanical engraving to laser engraving, allowing for more efficient and precise markings on our products. Additionally, the implementation of proof testing for each component ensured quality and reliability.